In the evolving landscape of industrial connectivity, the role of an Industrial Router is pivotal. According to Dr. Emily Wong, a leading expert in industrial networking, "An Industrial Router is essential for maintaining operational efficiency." This statement highlights the growing reliance on robust routers in industrial environments.

Industrial Routers facilitate seamless communication between devices. They manage data transfer across complex networks, ensuring reliability. In factories, these routers connect machinery, allowing real-time monitoring. They play a crucial role in the Internet of Things (IoT), enabling smarter systems. However, not all routers can handle harsh conditions. Environmental factors can affect their performance, raising concerns about durability and efficiency.

While these devices are vital, challenges remain. Ensuring cybersecurity is paramount, yet many industries struggle with this aspect. The integration process can be complicated, leading to potential downtime. This necessitates ongoing evaluations to improve these systems. By addressing these issues, we can harness the full potential of Industrial Routers for enhanced productivity.

An industrial router is a specialized device designed for industrial environments. It connects different networks and allows data exchange between devices. Unlike standard routers, industrial routers can withstand harsh conditions. They resist dust, moisture, and extreme temperatures. This makes them suitable for manufacturing plants and remote sites.

The functionality of an industrial router is straightforward but crucial. It uses protocols to manage data traffic. This ensures reliable communication in real-time systems. Many industrial routers support VPNs, enhancing data security. They provide remote access to equipment, allowing for quick troubleshooting. However, the complexity of setup can be a barrier for some users. A lack of technical knowledge may lead to misconfigurations.

The need for robust connectivity drives the demand for these routers. In IoT applications, they play a vital role. They enable devices to share data seamlessly. However, the evolving technology landscape demands constant updates. Companies may struggle to keep pace with advancements. This ongoing challenge highlights the need for training and support in using industrial routers effectively.

Industrial routers play a crucial role in manufacturing and industrial environments. They ensure stable, secure connections in a field where downtime is costly. A key feature of industrial routers is their ability to operate in harsh conditions. Many are rated for extreme temperatures, dirt, and moisture. Reports indicate that over 70% of industrial operations face connectivity issues due to environmental factors.

Another important aspect is security. Industrial routers often include advanced security protocols. According to a recent study, 50% of industrial firms experienced cyber-attacks. A robust router can reduce these risks. Additionally, these routers support multiple communication protocols. They enable seamless integration with various IoT devices. This is essential for monitoring and control in real-time.

Moreover, reliability is non-negotiable. Industrial routers often have redundant systems to maintain connectivity. A common challenge is system aging; nearly 30% of installations need upgrades within five years. Regular reviews of hardware and software can mitigate this. Ultimately, ensuring your industrial router meets these performance criteria is vital for operational efficiency.

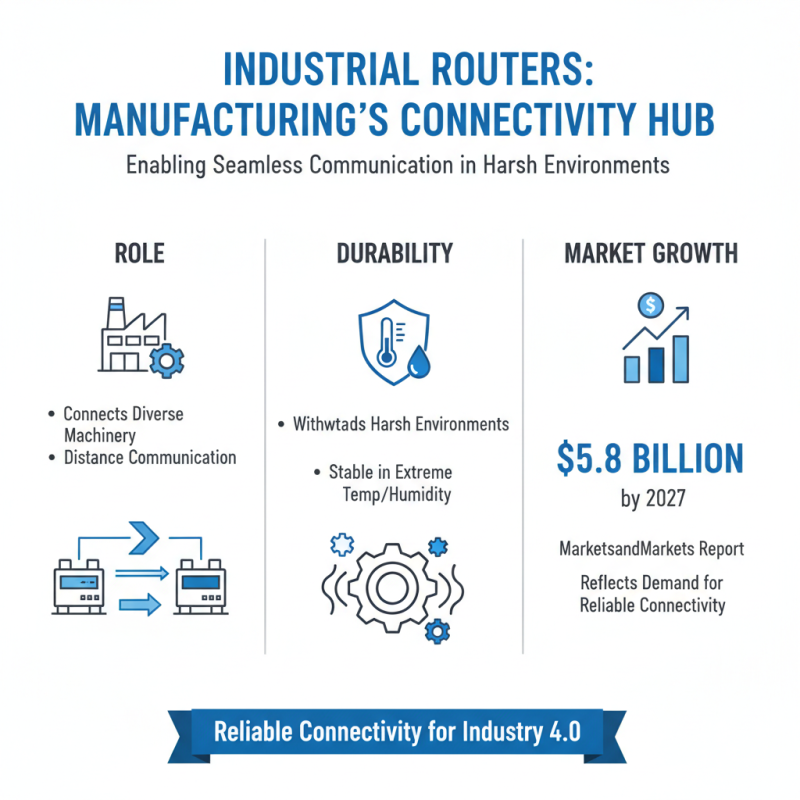

Industrial routers play a vital role in the manufacturing and production sectors. They connect various machines, ensuring seamless communication over large distances. These devices are designed to withstand harsh environments, ensuring stability in temperature and humidity. A report by MarketsandMarkets reveals that the industrial router market is expected to grow to $5.8 billion by 2027, reflecting increased demand for reliable connectivity in the industrial sector.

Mechanically, industrial routers function through a combination of hardware and software components. They manage data traffic effectively, prioritizing critical data packets. This is crucial, especially in environments where downtime can lead to significant losses. For example, a 2022 study indicated that production downtime costs manufacturers an average of $260,000 per hour. Such statistics highlight the router's importance in maintaining operational efficiency.

However, despite their advanced features, industrial routers can have vulnerabilities. Their reliance on external networks exposes them to potential cybersecurity threats. As industries evolve, the need for robust security measures becomes essential. Regular updates and maintenance can address these issues, but many facilities still face challenges. Balancing functionality and security is an ongoing process for many industrial operations.

Industrial routers play a crucial role across various sectors. In manufacturing, they enable real-time data transfer between machines. This connectivity allows for efficient monitoring and control of production lines. Sensors collect critical data, which is then sent to central systems for analysis. The ability to react quickly helps reduce downtime and increase output.

In the energy sector, industrial routers connect remote devices like turbines and grid sensors. This improves communication between locations and supports smart grid technology. Reliable data transmission is crucial here. Failures or delays can lead to significant issues. This area poses challenges that require constant attention and innovation.

Transportation also benefits from industrial routers. They enhance logistics systems by providing accurate tracking of shipments. Real-time updates help in managing delivery times effectively. However, vulnerabilities in these systems can introduce risks. The industry must continuously address cybersecurity and network reliability to safeguard operations.

| Industry | Application | Key Features | Benefits |

|---|---|---|---|

| Manufacturing | Machine-to-Machine Communication | Fast data transfer rates, reliable connectivity | Increased efficiency, reduced downtime |

| Transportation | Fleet Management | GPS tracking, real-time data analytics | Improved logistics, cost savings |

| Energy | Smart Grid Management | Secure communications, remote monitoring | Enhanced monitoring, better resource management |

| Healthcare | Telemedicine Services | Data encryption, low latency | Improved patient care, remote diagnostics |

| Retail | POS Systems Integration | High availability, cloud connectivity | Streamlined transactions, enhanced customer experience |

Industrial routers play a critical role in connectivity for various industries. They enable communication between machines, sensors, and control systems. These routers can function in tough environments where traditional routers may fail. Their reliability is vital in sectors like manufacturing and transportation.

Using industrial routers offers several benefits. One significant advantage is enhanced data transmission. These devices can handle larger amounts of data without losing quality. For example, an industrial router might transmit real-time data from a production line. This capability allows quick decisions, improving efficiency.

Moreover, industrial routers often support diverse protocols. This flexibility allows seamless integration into existing systems. Workers can monitor equipment and manage resources more effectively. However, some may find setup complex. Training is sometimes required. Not every team is prepared for this learning curve, which can pose challenges. Adopting such technology may not be as straightforward as it seems. Yet, the potential benefits often outweigh these initial hurdles.